Design

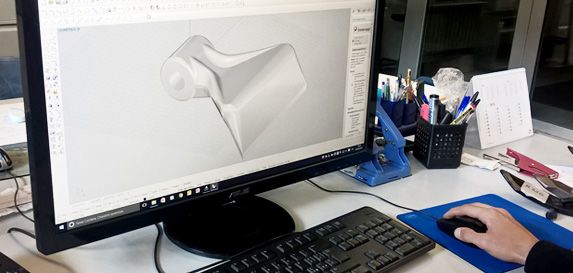

Our dies are created with modern integrated CAD-CAM systems, from product design with cutting-edge 3D software, to the production of models using latest-generation machine tools.

Our dies are created with modern integrated CAD-CAM systems, from product design with cutting-edge 3D software, to the production of models using latest-generation machine tools.

Once checked and stocked, materials are sent to the cutting line, entering the heart of the production process: Hot forging. Materials are heated using latest-generation induction ovens equipped with optical pyrometers for temperature control and dedicated systems that guarantee surface quality and maintenance of the steel characteristics.

Forging is performed using eccentric presses. We have automatic, semi-automatic and manual lines: while supporting the optimization of the production process, this ensures an excellent level of flexibility to meet all demands. Products are carefully checked throughout the entire process to maintain an adequate quality standard.

Experience, research and continuous development to refine our processes have led us to performing innovative heat treatments. This results in our products having extremely constant, homogenous hardness in terms of both the individual part as well as the entire production lot.

The result is a high quality product with excellent wear resistance and the proper resilience.

The hardness values are controlled systematically during both the hardening stage and the later tempering process. Thus, all parameters are controlled and nothing is left to chance.

Our product warehouse is well stocked and organized to meet any urgent requests our customers may have.

We continuously monitor stocks using a computer program that allows us to replace any missing parts quickly. We know that System Quality cannot lack in service.

In order to receive our catalogue, please fill in the fields below!